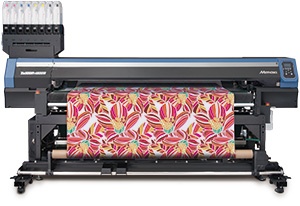

Mimaki Engineering Co., Ltd. (Headquartered in Nagano Prefecture, Tomi City; President, Kazuaki IKEDA), announced the release of a Roll to Roll UV-curable inkjet printer « UJV100-160 » with high quality and stable operation, available in limited areas from March 2020.

With two newly developed heads, the UJV100-160 has pursued high quality, high productivity, and stable operation as a UV-curable inkjet printer. Considering environmental issues and regulations around the globe, it adopts VOC (Volatile Organic Chemicals)-free UV-curable ink. Because the ink is cured instantly when UV light is irradiated after printing, the drying time that water-based or solvent ink requires is no longer needed. Also, the UV-curable ink can widely support commercially available media such as paper with no acceptance layer, PET film, and fabric, contributing to material cost reduction.

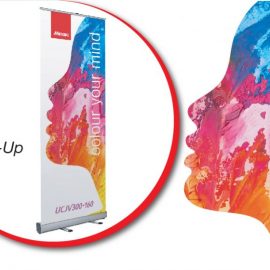

The UV-curable ink mounted on this printer is our newly developed « LUS-210 », which has six types: C, M, Y, K, W, and Cl*1. For ink set, there are three selectable variations: CMYK, CMYK+W, and CMYK+WCl. A combination of a white ink with superior concealing capability and the spot color ink of a shiny clear ink allows you to use this printer in various applications, from printing on transparent/colored media to highly creative varnish print.

In addition to NCU (Nozzle Check Unit) *2, NRS (Nozzle Recovery System) *3, and MAPS4 (Mimaki Advanced Pass System) *4 functions that enable stable and high-quality print, a new feature DAS (Dot Adjustment System) is also provided. Thanks to the DAS, conventional manual dot position correction and feeding amount correction are automated, reducing the burden on operators.